| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

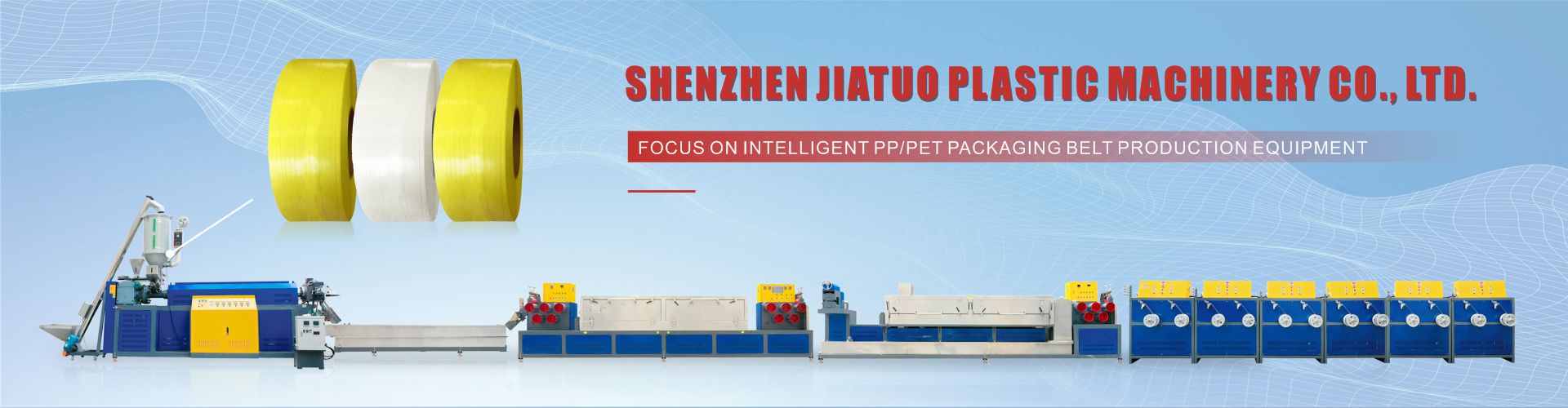

Brand Name : JIATUO CHINA

Model Number : JTPP-100

Certification : IS CEO

Place of Origin : CHINA

MOQ : 1 SET

Price : Negotiable

Payment Terms : L/C, T/T

Delivery Time : 30-40days

Packaging Details : plastic film

Strap Thickness : 0.4-1.2mm

Strap Width : 5-19mm

Warranty : 1 Year

Key Selling Points : Leading German And Japanese Advanced Technology

Power Consumption : 80KW

Strap Color : Red/ Green/ Black/ Yellow/ White

Screw diameter (mm) : 100mm

Applicable raw materials : Recycled Material And Polypropylene

The PP Strap Making Machine is a professional Polypropylene Strap Production Machine, leading the industry with its German and Japanese advanced technology. This highly efficient machine is capable of producing Polypropylene Straps, with a strap speed of over 260m/min and a strap thickness of 0.4-1.2mm. This machine is ideal for both Polypropylene Recycle Material and New Raw Material. The PP Strap Making Machine is the perfect choice for those looking for a reliable and efficient Polypropylene Strap Production Line.

| Product Attributes | Parameters |

|---|---|

| Extruder | Single or Double Screw |

| Warranty | 1 year |

| Strap Width | 5-19mm |

| Trademark | JiaTuo China |

| Applicable raw materials | Recycled Material and Polypropylene |

| Video outgoing-inspection | Provided |

| Strap Thickness | 0.4-1.2mm |

| Motor | Siemens |

| Strap Tension | Adjustable |

| Power Supply | 380V/220V |

1. This production line is specifically designed for manufacturing PP Straps. It features dual-output capability, producing 2 PP Straps simultaneously, resulting in 20%-30% energy savings.

2. The Shaping Water Tank and Calibrating Tank are constructed from high-quality stainless steel, ensuring durability and a long service life.

3. Equipped with a user-friendly PLC controller featuring touch-key operation and multi-language support, the system ensures safe and efficient operation. It maintains optimal performance of all components, guaranteeing stable production and continuous output of high-quality PP Straps.

① Feeding →② stirring →③ pre-drying →④ melting and measuring extrusion →⑤ embryo (belt embryo) cooling and forming →⑥ oven pre-heating →⑦ primary stretching →⑧ secondary stretching →⑨ embossing → oven tempering and setting → cooling → finished product winding

We offer technical support and service for our PP Strap Making Machine. Our technical support team provides professional assistance and advice to ensure that you get the most out of your machine.

If you have any questions or need any assistance, please don't hesitate to contact us.

|

|

Single Double Screw Pp Strap Making Machine With Printing 5-19mm Customized Automatic Wrapping Machine Images |